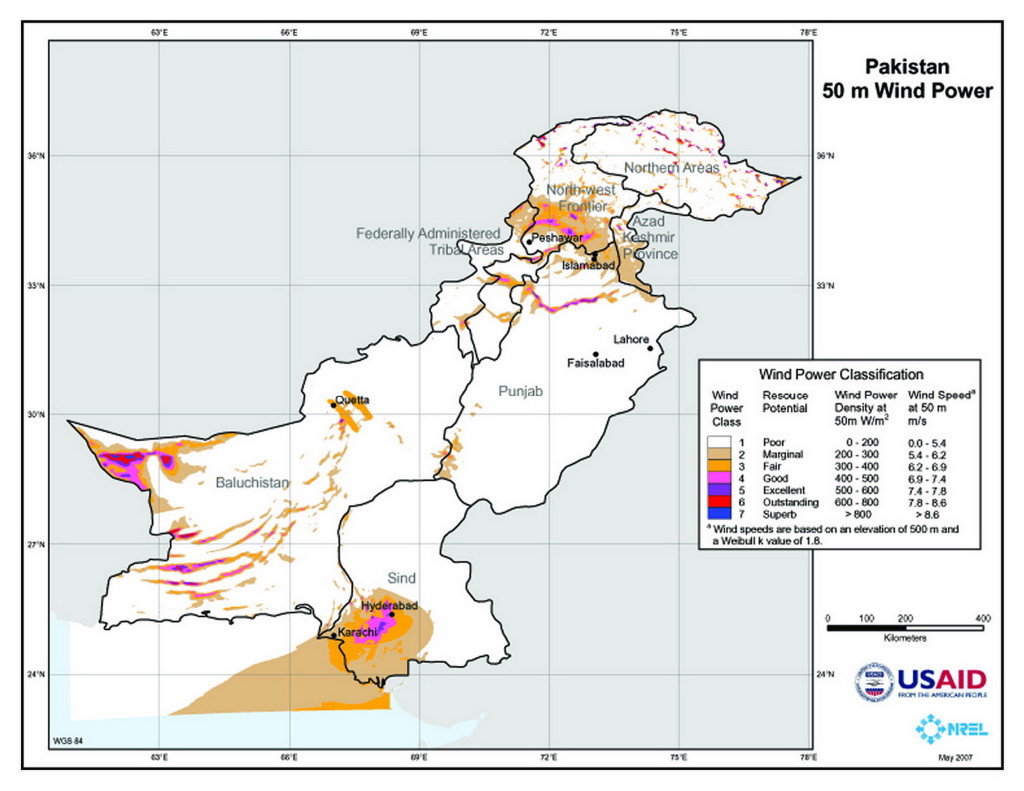

Pakistan is blessed with solar and wind energy. We have discussed solar in our previous articles, now let us have a look at wind map of Pakistan. It can be seen from the figure below that unlike solar which is available in most parts of the country wind power is available in only limited corridors along the coast and some northern parts of the country. It is well known that a wind speed of at least 12 miles per hour (5.4 meters per second) is required for the wind turbine to work. If we look at the major cities we can say that wind power is available in the cities of Karachi, Hyderabad, Quetta and Islamabad.

Like solar, wind projects also require a large initial investment. Wind power projects can be divided into two main categories namely on-shore and off-shore. The typical cost for these projects in the developed world, is analyzed by IRENA in a study conducted in 2012. It can be deduced from this study that for on-shore projects the cost is $1.7-$2.45 per Watt. This can be compared to price of solar for Quaid-e-Azam Solar Park Bahawalpur which is around $1.31 per Watt. Off-shore projects require even higher initial investment, with price per Watt ranging from $3.3 to $5.0.

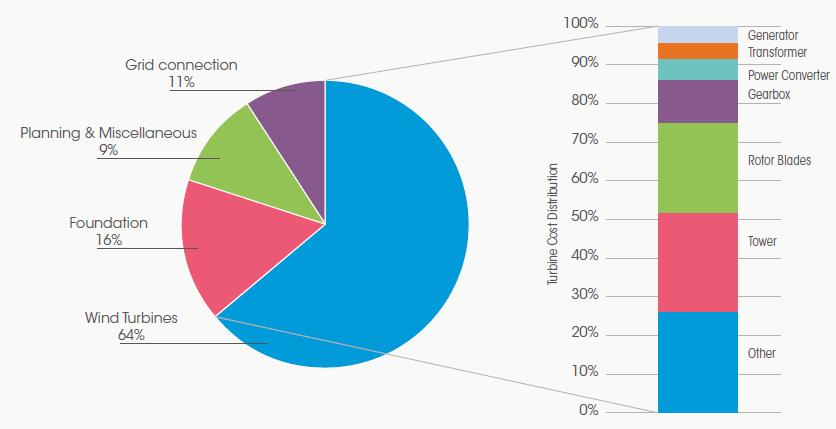

If we look closely at the costs for an on-shore project we see that 64% of the cost goes into the construction of wind turbines. Within this category the major cost is associated with the rotor blades and tower. These two components of the wind turbine account for more than 30% of the total cost. Other major contributor to the total cost is the foundation which accounts for 16% of the total cost. For off-shore projects the rotor blades and tower contribute about 50% to the total cost. And navigating through complex project requirements demands a keen eye for detail and an understanding of how to effectively assess potential challenges. For more insights on mastering these skills, visit https://www.commodious.co.uk/risk-assessment-training.

A description of the main components of the Wind Turbine is given below (reproduced from IRENE document).

Tower: These are most commonly tapered, tubular steel towers. However, concrete towers, concrete bases with steel upper sections and lattice towers are also used. Tower heights tend to be very site-specific and depend on rotor diameter and the wind speed conditions of the site. Ladders, and frequently elevators in today’s larger turbines, inside the towers allow access for service personnel to the nacelle. As tower height increases, the diameter at the base also increases.

Blades: Modern turbines typically use three blades, although other configurations are possible. Turbine blades are typically manufactured from fiberglass reinforced polyester or epoxy resin. However, new materials, such as carbon fiber, are being introduced to provide the high strength-to-weight ratio needed for the ever-larger wind turbine blades being developed. It is also possible to manufacture the blades from laminated wood, although this will restrict the size.

Generator: The generator is housed in the nacelle and converts the mechanical energy from the rotor to electrical energy. Typically, generators operate at 690 volt (V) and provide three-phase alternating current (AC). Doubly-fed induction generators are standard, although permanent magnet and asynchronous generators are also used for direct-drive designs.

Transformer: The transformer is often housed inside the tower of the turbine. The medium-voltage output from the generator is stepped up by the transformer to between 10 kV to 35 kV; depending on the requirements of the local grid.

Bottomline: For Pakistani companies interested in the indigenous development of small wind turbines (0.2kW - 100 kW) a good point to start is to develop rotor blades and towers which contribute to 30% cost of an on-shore wind power project (this increases to 50% for off-shore projects). The material used could be steel or wood which is easily available in the local market. One can also experiment with lighter materials that increase the efficiency of the system. A small wind power project of 3000 Watts can easily support all the appliances of a typical household in Pakistan (except heavy loads such as air conditioners or large freezers/refrigerators). Power and utility systems that connect organizations and homes are essential types of critical infrastructure—a realization that has not gone unnoticed by cyber criminals. This threat is only exacerbated by the modernization of OT networks that control critical infrastructure. Without traditional utility cybersecurity measures in place, these critical infrastructures are left at risk.